Bag Counter

The system Interface will include a baggage counter.

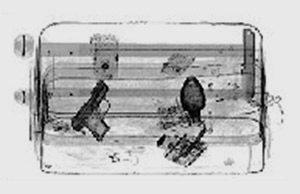

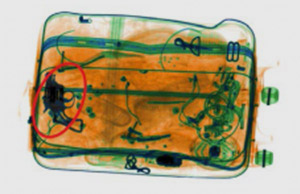

Colour Technology uses imaging analysis to assign colours based on the effective atomic number.

Our X Ray Baggage scanner with 8 Colours delivers greater accuracy and quickly helps to distinguish the potential threats. Our Dual Energy technology differentiates the contents, including liquids, explosives, and metallic materials, to help screeners quickly identify and isolate potential threats.

Our Enhanced technology will automatically enhance the images for operators, giving the security personnel time to effectively review each scan.

Pseudo colour feature will apply multiple colours to the screened image for additional colour differentiation as it adds an alternative imaging perspective to analyse screened objects.

Pseudo color 1

Pseudo color 1 Pseudo color 2

Pseudo color 2 Pseudo color 3

Pseudo color 3 Pseudo color 4

Pseudo color 4

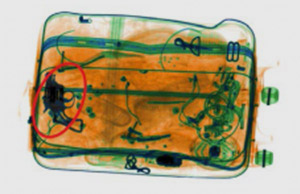

The Black and White colour feature discriminates between the objects, so the operator can easily distinguish between the items. Highly dense items will appear black on the screen enabling the operator to focus their attention on this area of the bag.

The High Penetration feature will allow the operator to adjust the darker regions of the image for better contrast and visibility ensuring continuous enhanced contrast.

This imaging feature will allow the operator to highlight organic or inorganic portions of the image. Please note the organic objects will be in orange while all other objects appear in grey.

Whereas inorganic objects will be in blue while all other objects remain grey. This is specifically used to target explosives or narcotics.

Organic Imaging

Organic Imaging Inorganic Imaging

Inorganic Imaging

The Black and White Reverse function provides an inverted grey scale display of a scanned image.

The system Interface will include a baggage counter.

Operators have an option to zoom in on a particular object or region of the x-ray image for greater clarity or object identification. With our Continuous Zoom, the operators can place the zoom cursor over the region of the x-ray image to zoom in up to 64X.

Density Alert draws an operator’s attention to potential threat objects by highlighting material that is too dense for x-rays to penetrate. In regular imaging mode, such objects appear black. Westminster offers two different types of Density Alert:

Standard: A standard system features a Density Alert that replaces an impenetrable object’s dark pixels with red pixels.

Edge Enhancement instantly improves the outline and shape of each object in the x-ray screen, this feature helps the operator to separate objects in the screened image and to quickly process if they represent a potential threat.

The X-Ray baggage scanners be supplied with separate sloped entry or exit roller tables compatible with the scanner ordered, available in 1, 2 & 3 metres lengths.

The system permits operators to review previously scanned images, the administrator can configure how many images the operator can review.

Operators can adjust the contrast of the image to either lighten or darken an area for improved image assessment. Westminster’s Light/Dark mode permits much finer increments of change, creating the effect of continuous transition.

Our interlock switches stop the x-ray generator and conveyor belt when an access panel is opened or removed.

TIP is a valuable detection tool for operators and administrators, the software has a large library with a range of threat objects and operates by periodically inserting a threat object into a scanned image.

When a threat object is detected, operators push the “Suspect” button on the AOCP to signify they recognize the threat. If the operator fails to identify a threat, the system will pause and the threat object will flash on the screen to notify the operator of the missed threat.

TIP exposes operators to various threat objects and provides further practice in threat identification. Moreover, TIP enables administrators to evaluate the threat detection capabilities of operators and ensure they are screening effectively. The TIP software may be enabled or disabled as desired from the administrator menu so as not to disrupt the standard screening process.

Our Continuous scanning feature activates the x-ray generator to scan smaller, lighter objects as sometimes the small, thin objects and/or mail occasionally fail to trigger the photo-sensors.

This is because the x-ray generator is only triggered when the photo-sensors located at the tunnel entry and exit identifies an object’s presence on the conveyor belt.

Optionally customers may specify a particular paint scheme to customise the exterior appearance of the x-ray machine. Customising the paint allows the x-ray system to blend into its surroundings and/or to reflect the clients corporate colour schemes.

Dual View Technology views objects from two angles – an “up shooting” view from beneath the object and a “side shooting” view from the side. The benefit is an improved ability to view odd-shaped objects (i.e. triangular or L-shaped), allowing operators to identify potential threats more quickly and easily than by using a single - view system.

The X-Ray baggage scanners be supplied with separate entry or exit roller tables compatible with the scanner ordered, available in 0.5,1, 2 & 3 metres lengths.

An extended length throughput conveyor is available for X-Ray Baggage Scanners, allowing longer clearance, larger object and more baggage loading.

JPEG Conversion is an automated process that occurs when the operator logs out. Following log out, if JPEG Conversion is enabled, the software will automatically convert all image scans to JPEG format.

The interface features a separate login for Operators, Supervisors and Administrators with unique programmable passwords, the Multi-Tier Accessibility allows the customer to tailor each system with different levels of accessibility and functionality depending on their

All systems are equipped with Real-Time Diagnostics, this program continuously monitors system components including: power supply input voltage, x-ray generator, e-stop status, entry/exit sensors, temperature, and more.

The Real-Time Diagnostics screen is fully accessible for Supervisors and Administrators to review the overall system health and print status reports, in case of a system fault, the word “FAULT” will appear on the display task bar and a description of the fault will appear in the Message Log on the Diagnostics Screen, As a safety precaution, the conveyor belt and x-rays will stop automatically until the fault is resolved.

Real-Time Diagnostics permits system owners to monitor the system, and can prevent and/or resolve simple faults themselves, or if needed, via technical phone support.

The UPS ensures the power to the PC and electronics is not damaged or disturbed in case of a power outage or power surge. The UPS is programmed to initiate the PC to shut down and to preserve the battery after a pre-determined time has elapsed. Once power is restored, the PC restarts normally and the UPS is reset automatically.

Barcode scanning allows the operator to attach a package’s barcode data to its corresponding image. Should the image need to be recalled, the Image Archive can easily be searched by inputting the barcode.

The system Interface will include a baggage counter.

Our Continuous scanning feature activates the x-ray generator to scan smaller, lighter objects as sometimes the small, thin objects and/or mail occasionally fail to trigger the photo-sensors.

This is because the x-ray generator is only triggered when the photo-sensors located at the tunnel entry and exit identifies an object’s presence on the conveyor belt.

Operators have an option to zoom in on a particular object or region of the x-ray image for greater clarity or object identification. With our Continuous Zoom, the operators can place the zoom cursor over the region of the x-ray image to zoom in up to 64X.

Optionally customers may specify a particular paint scheme to customise the exterior appearance of the x-ray machine. Customising the paint allows the x-ray system to blend into its surroundings and/or to reflect the clients corporate colour schemes.

Density Alert draws an operator’s attention to potential threat objects by highlighting material that is too dense for x-rays to penetrate. In regular imaging mode, such objects appear black. Westminster offers two different types of Density Alert:

Standard: A standard system features a Density Alert that replaces an impenetrable object’s dark pixels with red pixels.

Dual View Technology views objects from two angles – an “up shooting” view from beneath the object and a “side shooting” view from the side. The benefit is an improved ability to view odd-shaped objects (i.e. triangular or L-shaped), allowing operators to identify potential threats more quickly and easily than by using a single - view system.

Edge Enhancement instantly improves the outline and shape of each object in the x-ray screen, this feature helps the operator to separate objects in the screened image and to quickly process if they represent a potential threat.

The X-Ray baggage scanners be supplied with separate entry or exit roller tables compatible with the scanner ordered, available in 0.5,1, 2 & 3 metres lengths.

The X-Ray baggage scanners be supplied with separate sloped entry or exit roller tables compatible with the scanner ordered, available in 1, 2 & 3 metres lengths.

An extended length throughput conveyor is available for X-Ray Baggage Scanners, allowing longer clearance, larger object and more baggage loading.

The system permits operators to review previously scanned images, the administrator can configure how many images the operator can review.

JPEG Conversion is an automated process that occurs when the operator logs out. Following log out, if JPEG Conversion is enabled, the software will automatically convert all image scans to JPEG format.

Operators can adjust the contrast of the image to either lighten or darken an area for improved image assessment. Westminster’s Light/Dark mode permits much finer increments of change, creating the effect of continuous transition.

The interface features a separate login for Operators, Supervisors and Administrators with unique programmable passwords, the Multi-Tier Accessibility allows the customer to tailor each system with different levels of accessibility and functionality depending on their

Our interlock switches stop the x-ray generator and conveyor belt when an access panel is opened or removed.

All systems are equipped with Real-Time Diagnostics, this program continuously monitors system components including: power supply input voltage, x-ray generator, e-stop status, entry/exit sensors, temperature, and more.

The Real-Time Diagnostics screen is fully accessible for Supervisors and Administrators to review the overall system health and print status reports, in case of a system fault, the word “FAULT” will appear on the display task bar and a description of the fault will appear in the Message Log on the Diagnostics Screen, As a safety precaution, the conveyor belt and x-rays will stop automatically until the fault is resolved.

Real-Time Diagnostics permits system owners to monitor the system, and can prevent and/or resolve simple faults themselves, or if needed, via technical phone support.

TIP is a valuable detection tool for operators and administrators, the software has a large library with a range of threat objects and operates by periodically inserting a threat object into a scanned image.

When a threat object is detected, operators push the “Suspect” button on the AOCP to signify they recognize the threat. If the operator fails to identify a threat, the system will pause and the threat object will flash on the screen to notify the operator of the missed threat.

TIP exposes operators to various threat objects and provides further practice in threat identification. Moreover, TIP enables administrators to evaluate the threat detection capabilities of operators and ensure they are screening effectively. The TIP software may be enabled or disabled as desired from the administrator menu so as not to disrupt the standard screening process.

The UPS ensures the power to the PC and electronics is not damaged or disturbed in case of a power outage or power surge. The UPS is programmed to initiate the PC to shut down and to preserve the battery after a pre-determined time has elapsed. Once power is restored, the PC restarts normally and the UPS is reset automatically.

Barcode scanning allows the operator to attach a package’s barcode data to its corresponding image. Should the image need to be recalled, the Image Archive can easily be searched by inputting the barcode.